Features of GrapeNet

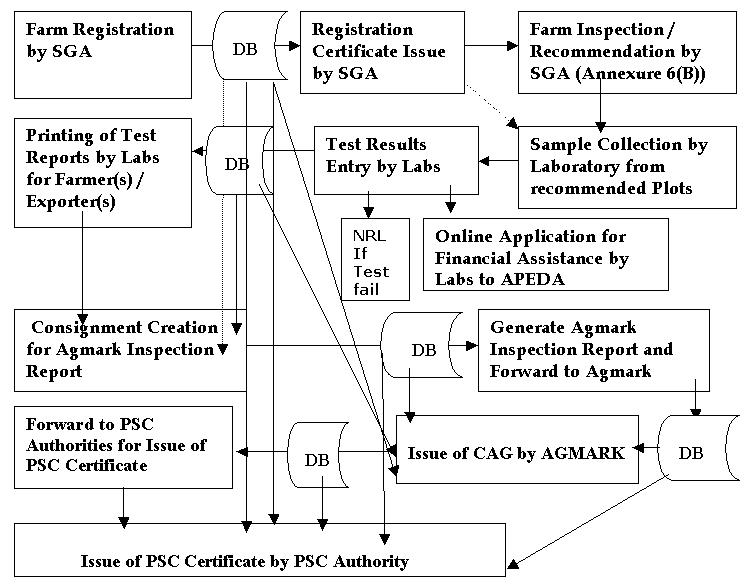

This software system integrates all stakeholders in the supply chain of grapes export, namely The Farmers, State Government Horticulture Departments, The testing laboratories, Agmark Certification Department, The Phyto-sanitary department, Pack houses, Exporters, and APEDA. GrapeNet has been very well received and actively been participated by all stakeholders in the supply chain and every consignment of fresh grapes during the season 2007 from India to European Union was monitored through this system. This system permits its stakeholders to carry out the following activities involved in the grapes export process as indicated in the diagram below.

It facilitates the State Horticulture departments to tabulate their inspection details on completing their visits to the farms, after which they can recommend to the Laboratories to take samples for testing for pesticide residues. Farmers can approach any of the APEDA recognized laboratories for testing their produce. The recommendation is mandatory and it is at the plot level.

The Laboratories record the details of the samples drawn from each plot for testing and conduct stringent testing for about 90 pesticides for residue levels. This system automatically finds out from the test measurements entered whether the sample qualifies for export to specified countries and generates their test reports. These laboratories are among the best in the world, have high precision and calibrated equipments, use validated procedures and are ISO 17025 compliant. Each plot is tested for pesticide residues.

In case the tests fail, the National Referral Laboratory or NRL is informed and they confirm whether an internal alert is required for this farm’s produce, restricting it from export to European Union. Exporters can only source produce from the plots of the farmers whose samples pass through these tests. Then they proceed to apply for the necessary AGMARK certification for quality and grade. At this stage, they provide the lot details, listing the registration numbers of the plots, from where he has sourced. Exporters are identified by their APEDA registration number.

District AGMARK officers employ accredited laboratories to check compliance for their standards through a physical inspection at the pack house where these lots are being put together to create consignment for export.

Before proceeding for their inspection, the laboratories use the online system to generate a unique Agmark Inspection ID for each lot to be inspected and this ID is pasted on the pallet of Grapes. Only those lots are accepted by the system that have passed the residue tests for the destination country. After this inspection, an ID for the Certificate of Agmark Grading or CAG ID is created by the laboratories, listing out the individual Agmark Inspection Report IDs covered under them for this particular consignment of an exporter. AGMARK Officers issue AGMARK Certificate or CAG to the Exporter based on this, through this integrated software. The plot number of farmer and Exporter Registration Number are all linked at this stage to the Agmark Inspection ID and to the CAG ID.

The next in the chain are the Phyto-sanitary departments at district level who carry out verification of the consignment at the registered pack houses and issue Phyto-sanitary certificates through this system. CAG is mandatory for issue of Phyto-Sanitary Certificates.

Once this comprehensive, 360 degree evaluation procedure is complete, the consignment is declared fit & ready for shipment!